Roll Up Doors in America: Easy Guide

Roll Up Doors in America: Easy Guide

Roll up doors are all over America. You see them at big warehouses in Ohio. Small car shops in Texas use them. These doors help businesses work better every day. Why do people like them? How did they beat swing doors? Roll up doors show how Americans fix problems.

Why Americans Pick These Doors

Americans like things that work well and save time. Roll up doors do both. Europe uses different doors. Americans picked roll up doors for one reason. They save space. Land costs money here. Every foot counts.

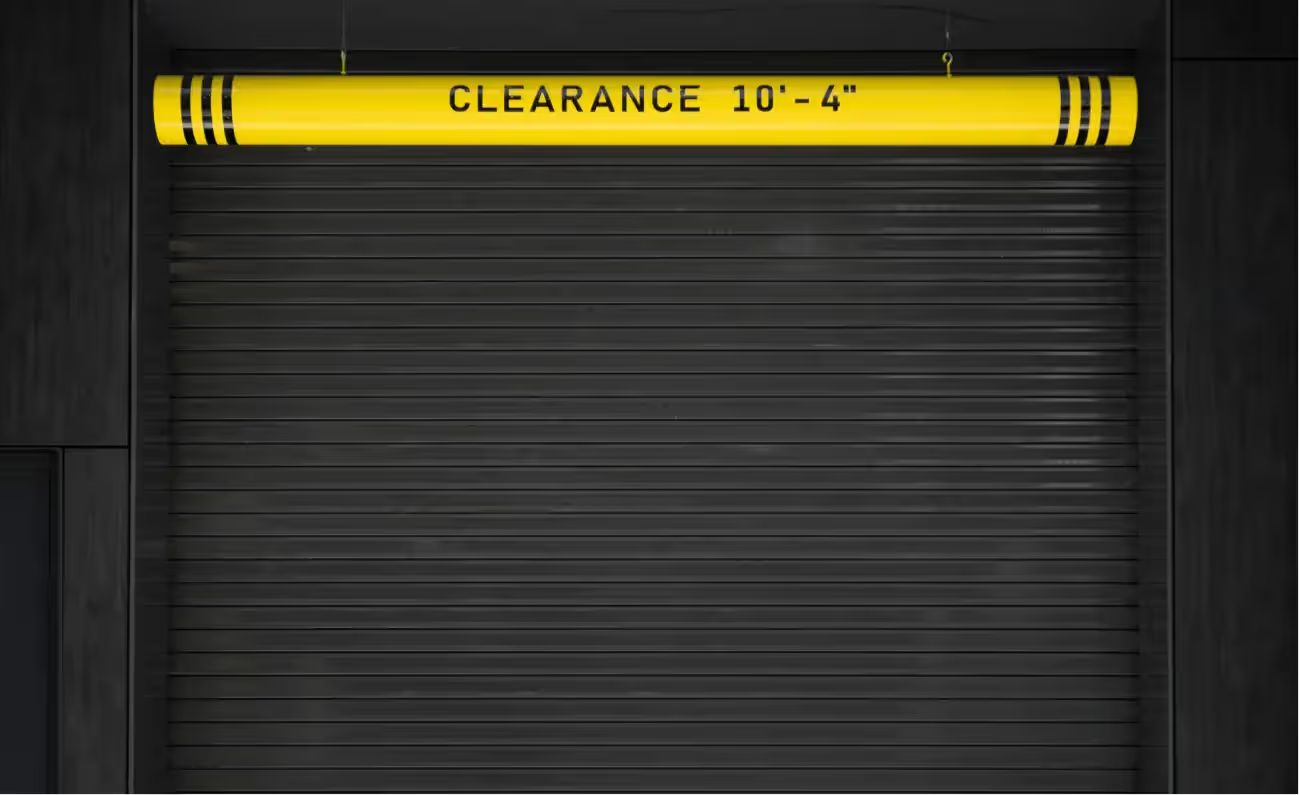

Think about a warehouse. A swing door needs 12 to 15 feet of space to open. Many loading docks means thousands of feet. That space could make money. Roll up doors fix this. They need almost no floor space when open.

This became big after World War II. American factories grew fast. Factory owners needed doors that saved space. They also needed security and weather protection. Roll up doors did all these things.

How These Doors Work

American roll up doors are built strong. They are different from doors made for mild weather. American doors must handle everything. Hurricane winds in Florida. Cold weather in Minnesota. They handle it all.

A door has flat pieces called slats. These slats connect with hinges. This lets the door bend as it moves up. The door rolls around a drum above the opening. This drum uses springs or motors to lift the door. It is one of the best door ideas ever made.

What makes American doors special? The strong way they are built. The slats are made from steel or aluminum. These materials fight rust and damage. This is smart for American weather and heavy use.

Weather sealing on American doors works well. Bottom seals must handle sand and snow. Side seals must work through big temperature changes. In Denver, morning temps might be 20 degrees. Afternoon temps can hit 70 degrees. That is a 50-degree change in hours.

Different Places Need Different Doors

American roll up doors change based on where they are used. What works in Southern California might fail in North Dakota. This created many types of doors.

In hurricane areas, doors have extra strong builds. They have special wind ratings. These tell you how much wind they can handle. These doors must meet tough building rules. This protects buildings against big storms. The slats might be thicker. The mounting parts are stronger.

Go to Midwest factory areas. You will find doors built for heavy use. Factories in Michigan or Ohio might open and close doors hundreds of times each day. These doors have heavy motors and strong springs. They use special oils that work in hot and cold weather.

The desert Southwest has its own problems. Doors must handle rough dust and strong sun. They must handle big temperature swings. Door makers created special coatings and materials for these tough conditions.

In the Pacific Northwest, keeping water out is the main concern. Doors here often have better rust protection. They have special drainage systems. The area gets heavy rain. This demands better protection.

New Technology

The last 20 years brought big technology changes. Simple devices became smart systems. They connect to building networks and security systems. They connect to phone apps.

Smart door technology is popular with American businesses. These systems let building managers watch door status from anywhere. They can track use patterns. They get alerts about repairs through phone apps. Some systems can predict problems before they happen. They can schedule repairs by themselves.

Connecting to security systems is another big step. Modern doors can use card readers and fingerprint scanners. Some high-security places have doors that can lock down when there is a threat. They create a solid barrier in seconds.

Energy efficiency became a major selling point in America. Special motor controls let motors run at the best speeds. This cuts energy use a lot. Better insulation systems help control temperature. This is important for cold storage places.

Installing Doors

Installing roll up doors in America has unique challenges. These challenges change based on location and how the door will be used. American buildings are very different from each other. Install teams must be flexible to handle all types of jobs.

You might work on old brick warehouses in Detroit one day. The next day you work on new steel buildings in Phoenix. Each job has its own problems. Old buildings have some of the hardest install jobs. Many American cities have strict rules about changing old building fronts.

Install teams created new mounting systems to handle these challenges. These systems give modern features while keeping the old look that cities want. This might mean custom brackets that work with old stone. Or special tracks that follow the shape of old archways.

Earthquake issues play a big role on the West Coast. California has tough earthquake rules. Doors must keep working even after big earthquakes. This led to special flexible mounting systems. These systems stop doors from getting stuck during earthquakes.

Big temperature changes in many American areas create unique install challenges. In places where temps can swing 100 degrees or more, metal expansion becomes important. Door tracks must handle this movement. They cannot stick or create gaps that hurt weather sealing.

Rules and Laws

The American roll up door industry works under many rules. These rules change by state and county. They change by individual cities. Understanding these rules is important. Anyone who specs, installs, or fixes these systems needs to know them.

At the federal level, OSHA sets workplace safety rules. These rules affect door design and installation. The rules cover emergency exit needs and machine safety standards. Following them is required by law. Breaking them can mean big fines and legal trouble.

Building codes add another layer of rules. The International Building Code gives a foundation. But individual states and cities often add their own special needs. Fire departments might require specific opening sizes. Zoning boards might limit noise levels.

Energy codes became more important recently. Many states now require business buildings to meet specific energy efficiency standards. This affects what type of door you can choose. Insulated doors and efficient motors are often needed to meet these rules.

Wind load ratings deserve special attention in America. With more frequent severe weather events, many areas made their wind resistance rules stronger. Doors must be tested and certified to handle specific wind speeds. You must give documentation to building officials to prove this.

Taking Care of Doors

American businesses developed a unique approach to door maintenance. This reflects broader cultural attitudes toward keeping equipment reliable. The old "run it until it breaks" thinking has given way to smart preventive maintenance programs.

The typical American business now follows maintenance schedules. These would have seemed too much one generation ago. Monthly checks and oil changes every three months became standard practice. This shift reflects that modern doors are more complex than older ones.

Predictive maintenance technology found good ground in America. Vibration sensors and heat imaging help building managers find potential problems. They find them before they cause costly breakdowns. This technology-driven approach appeals to American managers who like data-driven decisions.

The parts and service network in America evolved to support this maintenance culture. National service networks make sure that replacement parts are available. Qualified technicians are available even in remote locations. Some manufacturers keep regional distribution centers. This guarantees next-day parts delivery anywhere in the continental United States.

Training programs became smarter. Many American companies now send their maintenance staff to manufacturer-sponsored training programs. These programs cover basic adjustments and advanced electronic diagnostics. This investment reflects the growing recognition that proper maintenance requires specialized knowledge.

Money and Market Forces

The roll up door industry represents a big segment of the American economy. Annual sales are measured in billions of dollars. This market includes simple manual doors for small businesses. It also includes sophisticated automated systems for major distribution centers.

Manufacturing stays concentrated in traditional industrial regions. The map has changed in recent decades. Companies in Ohio, Illinois, and Pennsylvania still dominate production. But production facilities in Texas, Georgia, and North Carolina have taken a good part of the market share.

Roll up door manufacturing comes from a complex ecosystem in America. Steel for the door slats might be purchased from mills in Indiana. Electronic components are often sourced from suppliers in California or Massachusetts. This distributed supply chain provides strength but also creates weak points. The COVID-19 pandemic highlighted some of these weaknesses.

Labor dynamics in the industry present both challenges and opportunities. The skilled trades shortage affects many American industries. It impacts roll up door installation and service. Companies responded by developing apprenticeship programs. They invested in training technologies. These allow workers to develop expertise more quickly.

The replacement market drives a significant portion of industry revenue. Many American business buildings contain doors installed in the 1980s and 1990s. These are approaching the end of their useful lives. This creates a steady stream of replacement opportunities.

Innovation Trends

American companies continue to lead global innovation in roll up door technology. This happens because of the unique demands of the domestic market. It also happens because of the competitive pressures of American business culture. Several trends are reshaping the industry.

Sustainability emerged as a major driver of innovation. American businesses increasingly demand doors that contribute to LEED certification. This spurred development of doors made from recycled materials. It spurred systems that improve building energy efficiency. It spurred manufacturing processes that minimize environmental impact.

Integration with smart building systems represents another major trend. Modern American business buildings feature sophisticated building management systems. These control lighting, heating, and cooling. Roll up doors are increasingly designed to integrate seamlessly with these systems.

Security integration continues to evolve. American businesses face unique security challenges. These include theft prevention and active shooter scenarios. Modern roll up doors can integrate with facial recognition systems. They can integrate with vehicle identification technology and emergency lockdown procedures.

Material science advances are opening new possibilities for door design. Carbon fiber reinforcement allows for lighter doors that maintain strength. New polymer compounds provide better weather resistance. They require less maintenance. Advanced coatings resist graffiti and reduce cleaning requirements.

Regional Manufacturing

The American roll up door manufacturing landscape tells an interesting story. Industrial evolution and regional specialization intersect here. Unlike many industries that moved production overseas, roll up door manufacturing stayed mostly domestic. This happened because of the need for customization and fast turnaround times.

The Great Lakes region continues to be the manufacturing heart of the roll up door market. Ohio, Michigan and Pennsylvania are close to steel suppliers. They have a large metalworking history and excellent transportation infrastructure. All of these manufacturers have invested in advanced equipment. This includes computer-controlled machines and robotic welding systems.

Texas is a big manufacturing center. This is especially true for doors going into the energy and petrochemical markets. The good business climate in Texas and close proximity to large industrial customers have drawn manufacturers. The Texas facilities generally manufacture heavy duty doors for tough industrial environments.

The Southeast is another area of significant expansion in roll up door manufacturing. This growth is driven partly by the region's economic development. It is also driven by the need to serve growing markets in Florida, Georgia, and the Carolinas.

Supply chain management in the American roll up door industry became increasingly sophisticated. Just-in-time delivery systems make sure that installation teams receive doors exactly when needed. This lowers inventory and storage costs. It increases project efficiency.

The parts distribution network deserves special recognition for efficiency. A small repair shop in rural Montana can get critical replacement parts within 24 hours. This is important because many roll up door applications are mission-critical. When a loading dock door is down, every hour of downtime costs money.

Custom Applications

Perhaps the most notable characteristic of the American roll up door market is the incredible diversity of applications. Like the American automobile market, the desire for customization follows closely behind. The American business customer has never embraced standardized solutions.

The food service industry has some of the most demanding applications. Doors in commercial kitchens need to be designed with serious concerns for hygiene. They must handle heat, moisture, and cleaning chemicals. Stainless steel is common. Food-grade polymers are often required. Designs must have no places for bacteria to grow.

Cold storage applications focus on maintaining temperature integrity. They must ensure operational reliability in sub-zero conditions. These often use specialized sealing systems and insulated panels. They use heating elements to prevent ice formation. The challenge becomes particularly critical in applications where doors need to transition between different temperature zones.

The pharmaceutical and biotechnology industries have the highest expectations for contamination control. Doors in these applications usually use specialized sealing systems. They use materials that resist chemicals in cleaning agents. Some applications use doors that can achieve pharmaceutical-grade cleanliness standards.

The auto industry developed its own set of specialized requirements. For paint booth applications, a roll-up door must resist exposure to cleaning chemicals. It must achieve precision tolerances in dimensional accuracy. For assembly line applications, doors must achieve high reliability with repeated operation throughout the day.

Aircraft hangars represent perhaps the most demanding application for roll up doors. These massive doors must span openings of 100 feet or more. They must withstand wind loads that would destroy conventional doors. The engineering challenges are immense.

Safety Standards

Safety considerations affect every aspect of roll up door design, installation, and operation in America. The litigious nature of American business culture created an environment where safety is the top priority. This combined with stringent regulatory requirements.

Entrapment prevention systems became increasingly sophisticated. This happened in response to both regulatory requirements and liability concerns. Modern doors feature multiple sensing technologies. These can detect the presence of people, vehicles, and objects in the path of a door.

Emergency exit provisions create unique challenges for roll up door applications. Many jurisdictions require that doors used as exits must operate without power. They must operate at a speed that promotes safe escape. This led to the development of special release mechanisms and backup power systems.

Fall protection plans are a large part of installation and maintenance procedures. Roll up doors are often installed at height. OSHA requires fall protection plans during installation and maintenance. Many manufacturers provide service platforms and safety anchor points in their standard designs.

Wind load safety became increasingly important as extreme weather events become more frequent. Doors must not only resist design wind loads. They must also fail safely if those loads are exceeded. This led to the development of specialized release mechanisms.

Fire safety integration represents another critical area. Many roll up doors must integrate with building fire suppression systems. They close automatically when smoke is detected. Or they remain open to help firefighter access.

Technology Integration

The integration of advanced technology into American roll up door systems reflects broader trends. Automation and data-driven decision making characterize American business today. These technological advances go far beyond simple remote control operation.

Building Information Modeling integration revolutionized how roll up doors are specified and installed in major construction projects. Door manufacturers now provide detailed 3D models. These allow designers and engineers to integrate the door into their building designs.

Predictive analytics capabilities enable facility managers to optimize door performance. This happens based on usage patterns and environmental characteristics. Systems can be programmed to optimize operational parameters. This minimizes wear, reduces wasted energy, and extends equipment lifetime.

Remote monitoring capacity proved useful to organizations with multiple facilities. For example, a retailer with hundreds of roll up doors nationwide can assess performance status of all their doors from one central location. This enables them to identify maintenance needs and schedule service calls.

Cybersecurity considerations emerged as doors became more interconnected. American businesses are sensitive to cybersecurity threats. Manufacturers of door systems established sophisticated security protocols. These include encrypted communications, secure authentication protocols, and regular security updates.

Environmental Considerations

Environmental considerations became a more important factor in the American roll-up door purchasing decision process. In some cases, environmental considerations are driven by regulations. In others they come from corporate environmental sustainability initiatives.

New advancements in variable frequency drives helped reduce motor energy consumption. These allow users to set the power and speed needed to operate a door efficiently. Many advanced insulated door systems provide an excellent way to control the thermal envelope of buildings.

The increased use of recycled content in door materials manufacturing increased. This happened in direct response to LEED and other green building product environmental compliance regulations. Most manufacturers now make doors that consist of a large amount of recycled steel content.

Improvements in manufacturing processes reduced environmental impact. This happened through enhanced material efficiency, waste reductions, and energy optimization. Powder coating removed the use of solvent paints and eliminated almost all VOC emissions.

Lifecycle assessment is now standard for documenting environmental impacts of roll-up doors. This accounts for environmental impact from raw material formation all the way to end-of-life disposal. Lifecycle assessment tools allow customers to make informed choices.

Future Outlook

The American roll up door industry stands at an interesting point. Traditional applications continue to grow while new technologies open entirely new market opportunities. Several trends are likely to shape the industry's future development over the next decade.

Self-driving vehicle integration represents a significant emerging opportunity. As self-driving trucks become more common in logistics operations, roll up doors will need to communicate directly with vehicle systems. This integration will require new sensing technologies and communication protocols.

Advanced materials continue to offer new possibilities for door design. Graphene-enhanced composites could provide unprecedented strength-to-weight ratios. Smart materials that change properties in response to environmental conditions could eliminate the need for separate sensing systems.

Artificial intelligence applications are beginning to emerge in door control systems. These systems can learn from usage patterns and environmental conditions. They optimize operations automatically. Future systems might predict maintenance needs weeks in advance.

Modular design concepts could revolutionize how doors are manufactured, installed, and maintained. Systems designed around standardized modules could be configured for specific applications. This approach could also simplify field service.

Energy generation capabilities represent an intriguing possibility for the future. Large roll up doors could incorporate solar panels or other energy generation technologies. This would turn them into net energy producers rather than consumers.

Human Stories

Behind every roll up door installation lies a human story. Take Jim Rodriguez, a third-generation installer based in Phoenix. He spent thirty-seven years working on doors across the Southwest. His weathered hands tell the story of countless installations in 120-degree heat. Installation crews start work at 4 AM to beat the sun.

"You can't just follow the manual out here," Jim explains while adjusting his tool belt. "Each job teaches you something new. I've installed doors in old missile silos and converted airplane hangars. Even a facility that makes those giant balloon animals for the Macy's parade. Every single one had its own personality."

Jim's experience shows something manufacturers often miss in their technical specifications. The human adaptability that makes American roll up door installations successful. While European installers might follow rigid protocols, American technicians developed an improvisational approach to problem-solving.

The learning curve for new installers remains steep despite advanced technologies. Mark Chen operates an installer certification program in Oakland. "It takes about three years for a technician to understand all the subtleties of a complex installation," Mark says. "You can teach someone to read blueprints in weeks. But helping them learn to sense when things aren't right takes time."

This experience becomes particularly important for retrofit installations in older buildings. Many of these are from early 20th century construction. Building standards were different back then. Installers often encounter surprises related to original construction.

Supply Chain Revolution

The American approach to roll up door supply chain management developed an almost military-like logistics strategy. Companies like Wayne Dalton and Overhead Door built distribution networks. These ship custom doors to anywhere in the continental United States within 72 hours of completion.

For most of the 1990s, manufacturers used traditional inventory models. They stored typical door sizes in regional warehouses. This worked well enough for standard applications. But it quickly broke down when customers requested expedited deliveries of custom doors.

The switch to faster timeframes began with advancement in manufacturing technology. This allowed manufacturers to deliver custom solutions quickly without sacrificing quality. Computer-aided roll forming equipment could build doors of almost any size. Automated powder coating lines could apply custom colors without lengthy setup times.

But technology alone didn't solve the logistics challenge. Companies had to completely reimagine their distribution strategies. They moved from centralized warehousing to a network of strategically positioned service centers.

The sophistication of modern door logistics becomes apparent during peak construction seasons. Summer months see demand surge by 40-60%. Contractors rush to complete projects before winter weather arrives. Manufacturers developed predictive algorithms that analyze historical patterns.

FedEx and UPS became integral partners in door distribution. Some manufacturers developed specialized packaging. This allows doors up to 20 feet wide to ship via standard freight networks. The packaging innovations alone represent millions of dollars in development investment.

Quality Control

American manufacturing culture always emphasized quality. But the roll up door industry took this focus to extraordinary levels. Modern manufacturing facilities employ quality control systems that would make aerospace manufacturers envious.

At a typical American door manufacturing facility, quality control begins before raw materials enter the building. Steel coils undergo chemical composition analysis and dimensional verification. Electronic components receive burn-in testing that simulates years of operation in compressed testing times.

The manufacturing process includes multiple inspection points. Some inspection points require measuring fixtures that check door dimensions within thousandths of an inch. Other inspection points use automated systems that photograph each weld joint. These use artificial intelligence to identify defects that a human inspector might miss.

Most significant is that manufacturers fostered a culture of continuous improvement. This goes beyond any formal quality system. Employees on production lines are encouraged to provide recommendations for improving processes. This type of improvement is rewarded with cash bonuses or public recognition.

The focus on quality includes performance tracking in the field. Many manufacturers attach sensors to doors that transmit performance data back to the factory. This real-world feedback loop allows engineers to identify design improvements.

The payoff from these quality investments becomes apparent in warranty statistics. Leading American manufacturers now offer warranties that would have been unthinkable in previous generations. Twenty-year structural warranties and five-year coverage on electronic components became standard.

Weather Engineering

American weather presents challenges that European or Asian door manufacturers rarely encounter. The continental climate creates scenarios where a single door might need to operate in 40-below-zero conditions one month and 110-degree heat the next. Add hurricane-force winds, hail storms, and the occasional tornado.

Hurricane engineering represents one of the most sophisticated aspects of American door technology. Doors destined for hurricane-prone regions undergo testing in specialized facilities. These can generate wind speeds exceeding 200 miles per hour. They simultaneously bombard the doors with projectiles that simulate wind-borne debris.

These tests revealed counterintuitive design principles. Traditional engineering wisdom suggested that stronger, more rigid doors would better resist wind loads. But testing showed that doors with some controlled flexibility actually performed better. They absorb wind energy rather than fighting it directly.

The development of hurricane-resistant doors required collaboration between door manufacturers, structural engineers, and meteorologists. Computer modeling aided design optimization. But nothing finally beats real-world testing. Thousands of doors along the Texas coast provided an unintended field test during Hurricane Harvey in 2017.

Cold weather engineering presents different but equally challenging obstacles. Doors intended for operation in northern climates must remain flexible at temperatures when steel becomes brittle. Lubrication systems must continue working when traditional oils become thick as honey.

The solution was to develop advanced materials and create new processes. Low-temperature lubricants borrowed from aerospace ensure mechanisms still move. Sealing compounds were developed for extremely low to extremely high temperatures.

Custom Manufacturing

While the vast majority of American manufacturing follows mass production principles, the roll up door industry nearly always used an artisan approach to customizable manufacturing. The benefit for US manufacturers is that customization creates a unique competitive advantage.

Take for example a brewery in Vermont that wanted a door for their fermentation building. They needed a door that could handle high humidity and occasional caustic cleaning chemicals. They also needed tight temperature control. The solution required custom stainless steel slats and specialized sealing systems.

Consider also the case of a data center in Phoenix that needed doors for their emergency generator facility. These doors had to withstand desert conditions while providing acoustic isolation to meet city noise ordinances. The solution involved composite slats with integrated sound dampening materials.

These custom applications represent far more than simple modifications to standard products. They require deep engineering analysis and material testing. Often they require the development of entirely new manufacturing processes.

The customization capability extends beyond individual product features to complete system integration. A pharmaceutical facility might require doors that integrate with their building management system and contamination control protocols.

Training Programs

As the roll up door industry grew more sophisticated, the challenge of maintaining skilled technicians became increasingly critical. The baby boom generation that developed much of the industry's expertise is nearing retirement. Recruiting younger workers to trades is difficult. So industry leaders created comprehensive training programs.

These training programs blend traditional apprenticeship programs with modern distance education. The programs recognize that today's technicians need skills much broader than mechanical reasoning. They need to understand electronics and computer systems.

The most successful training programs combine classroom education with extensive hands-on learning. Students learn door theory in climate-controlled classrooms with interactive simulators. Then they apply that knowledge in workshop environments that provide real-world installation problems.

These training programs teach problem resolution skills rather than rote memorization. Modern installations rarely resemble textbooks. The successful technician must understand how to modify standard procedures to accommodate unusual situations.

A few manufacturers created virtual reality training systems for students to practice installations in simulated environments. With virtual reality systems, students can practice installations in situations that would be dangerous or unusual without risking health and safety.

Community colleges emerged as key partners in delivering this training. Programs at institutions such as Gateway Technical College in Wisconsin created curriculum for the door industry.

Energy Economics

Energy efficiency transitioned from a nice-to-have product feature to a key economic driver in the American roll up door market. This reflects a much larger shift in American business culture as sustainability programs matured.

The case for energy-efficient doors often surprises facility managers who focus primarily on purchase price. A high-performance insulated door may cost 40% more upfront than a basic door. However, energy savings pay for this extra cost in two to three years of operation.

The business case for energy-efficient products becomes more attractive with the type of facility and heating or cooling loads. For example, an insulated door on a -10 degree freezer in cold storage could save hundreds of thousands of dollars over time.

Variable frequency drives represent an additional energy efficiency opportunity. These drives allow door motors to operate at the most efficient speed and torque instead of fixed-speed operation. This can reduce energy usage by 20-30% in typical applications.

Smart control systems add another layer of efficiency. They optimize door operations based on facility usage patterns. These systems can automatically adjust opening and closing speeds based on traffic patterns.

The utility incentive landscape created additional economic incentives for energy-efficient doors. Many electric utilities offer rebates for equipment that reduces peak demand. High-performance doors often qualify for these programs.

Security Integration

The security landscape for American businesses evolved dramatically over the past two decades. Roll up doors adapted to meet increasingly sophisticated threat scenarios. Modern security integration goes far beyond traditional lock-and-key approaches.

Access control integration represents the most common security enhancement for roll up doors. Modern systems can integrate with employee badge systems and biometric scanners. These integrations allow facility managers to track who accessed which areas and when.

For loading dock applications, vehicle identification came into play to improve loading and unloading of materials. The use of vehicle identification by door automation provided a centralized approach to identifying approved delivery vehicles.

Video surveillance systems became more sophisticated in their integration with security measures. Doors can now be programmed to record when activated. All aspects of access events can be recorded. Some systems use facial recognition technology.

As doors became more interconnected, cybersecurity became more relevant. American businesses take cyber security risks seriously. Manufacturers of door systems created secure protocols for networked programmable doors.

Emergency lockdown options represent perhaps the most sobering aspect of integrating security with programmable doors. Some facilities can now limit access to a building based on a recognized security threat.

Material Science

Material science for roll up doors changed dramatically in recent decades. This happened due to advances in metallurgy, polymer chemistry, and composites manufacturing. These advances developed material performance characteristics that were not even imagined in traditional manufacturing.

Advanced steel alloys provide improved strength-to-weight ratios. These permit lighter doors while maintaining performance characteristics. High-strength low-alloy steels use small amounts of alloying elements such as vanadium and niobium.

Modern aluminum doors typically use alloys specifically designed for architectural applications. These have higher corrosion resistance and improved thermal performance. Some alloys include magnesium or other elements in small percentages.

Polymer technology changed the game for sealing systems and impact resistance. Modern weather seals now use thermoplastic elastomers that remain flexible at extreme temperature ranges. These materials can withstand hundreds of thousands of compression cycles without deterioration.

Composite materials represent the future of door construction. Carbon fiber reinforced polymers can reduce weight by 60% compared to steel while maintaining exceptional strength. Though expensive for most applications, these materials are finding their way into specialized applications.

Coating technology continues to advance dramatically. Modern powder coating has durability performance that is multiple times better than older liquid paint systems. Some coatings include nanoparticles that provide self-cleaning properties.

Service Revolution

The service model for roll up doors transformed over the last decade. It moved from reactive maintenance to predictive analytics and proactive service delivery. The advancements in door service follow trends in industrial maintenance.

In the past, door service revolved around break-fix operations. Technicians arrived on-site when a door failed. This usually happened during emergency service calls outside traditional business hours. The break-fix approach led to costly repairs and prolonged downtime.

Predictive technology became the basis for modern predictive maintenance door service programs. Sensors monitor many aspects of door functionality including motor vibration and door balance. Service technicians analyze all collected data to identify potential problems weeks before they become failures.

The sophistication of modern monitoring systems extends beyond standard mechanical parameters. Advanced monitoring systems record doors in operation and usage patterns. They record any deviations from normal operation that might indicate developing problems.

Remote diagnostics capability allows service technicians to troubleshoot problems often without making a site visit. Remote diagnostics provide major benefits for customers with multiple locations.

The evolution from traditional service to predictive maintenance appears in new service contract models. Modern service contracts guarantee response times and predictive maintenance services. They guarantee performance and in some cases even energy efficiency guarantees.

Conclusion

The story continues to unfold for roll up doors in America. It continues with the same innovation, adaptation, and relentless pursuit of improvement that characterized the industry since its beginning. New global challenges for American businesses provide more opportunities for roll up door technology to advance rapidly.

The ability for this industry to adapt to new challenges reflects greater strengths in American manufacturing culture. This includes investment in research and development and emphasis on customer-driven innovation. It includes commitment to quality that made American-manufactured doors the global standard.

Looking toward the future, the roll up door industry stands ready to play an increasingly important role in American infrastructure. As supply chain efficiency becomes more critical and energy costs continue to rise, the humble roll up door will undoubtedly continue to adapt and improve.

The human element remains central to this success story. Behind every technological advancement and installation success lies the expertise and dedication of the people who design, manufacture, install, and service these essential components of American commerce. Their continued commitment to excellence ensures that the American roll up door industry will continue to set global standards for generations to come.